Overview

Discover the power of edge computing

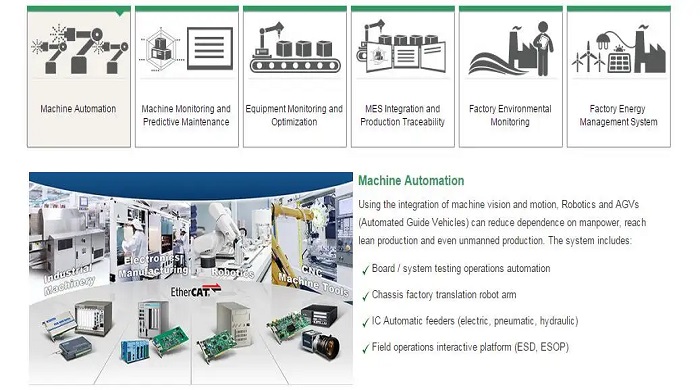

The massive growth of IoT devices, the increasing fragmentation of data sources, and the growing need for remote operations continue to drive the demand for edge computing. Edges bring the application’s data store closer to the point of action. Edge computing has the ability to transform the industry by combining 5G and ARTIFICIAL intelligence.

BesTom’s Edge services provide a roadmap for hybrid cloud and edge computing to run workloads at scale, co-creating and edge-powered AI solutions, applications, and platforms.

Brief introduction

In the era of Industry 4.0, products and services will rely on the Internet and other network services, through the combination of software, electronics and environment, to produce new products and services, completely different from the traditional production mode of intelligent manufacturing mode.

First, the trend of individuation of product demand. Is the core of thinking in the industrial age 4.0, the user supreme, the user increasing influence on the allocation of resources, product design, the future of the terminal customers can more directly involved in product engineering and design, products can be fully carried out in accordance with the personal willingness to produce, even in extreme cases will be automated, personalized sheet manufacturing.

Second, the standardization requirements of the production platform. Industry 4.0 strategy is the key to establish a person, machine, the connectivity of the network society, all kinds of terminal equipment, data information exchange between application software, such as identification, handling, maintenance must be based on a set of standardized system, developed a single common standard, network connection and integration among different companies will become possible. The standardization of industry 4.0 not only involves the unification of hardware standards, but also the formulation of many software, requiring enterprises in the fields of machinery, processing and manufacturing, automation engineering and software to cooperate and unify standards.

The third is the modularization strategy of production mode. In order to effectively control the diversity of products, enterprises need to adopt a modular approach to production, improve efficiency and reduce costs. Only by classifying the personalized needs of products to meet the most critical common needs and setting up smaller production units can the personalized needs be met more economically. Germany has a lot of enterprises and research institutes to develop a new generation of production line jointly, the equipment that constitutes this kind of production line realized modularity, can change the equipment module freely according to the type of product produced, and after the equipment module is replaced, it can be put into use immediately, in order to promote the standardization and modularity of product design.

Feature